FCA snc performs cnc machining of wood for third parties; you can operate on solid wood, but also on other laminated wood materials (plywood, blockboard, etc.) and MDF.

Our processes

From prototyping to production

Our processes

Woodworkings

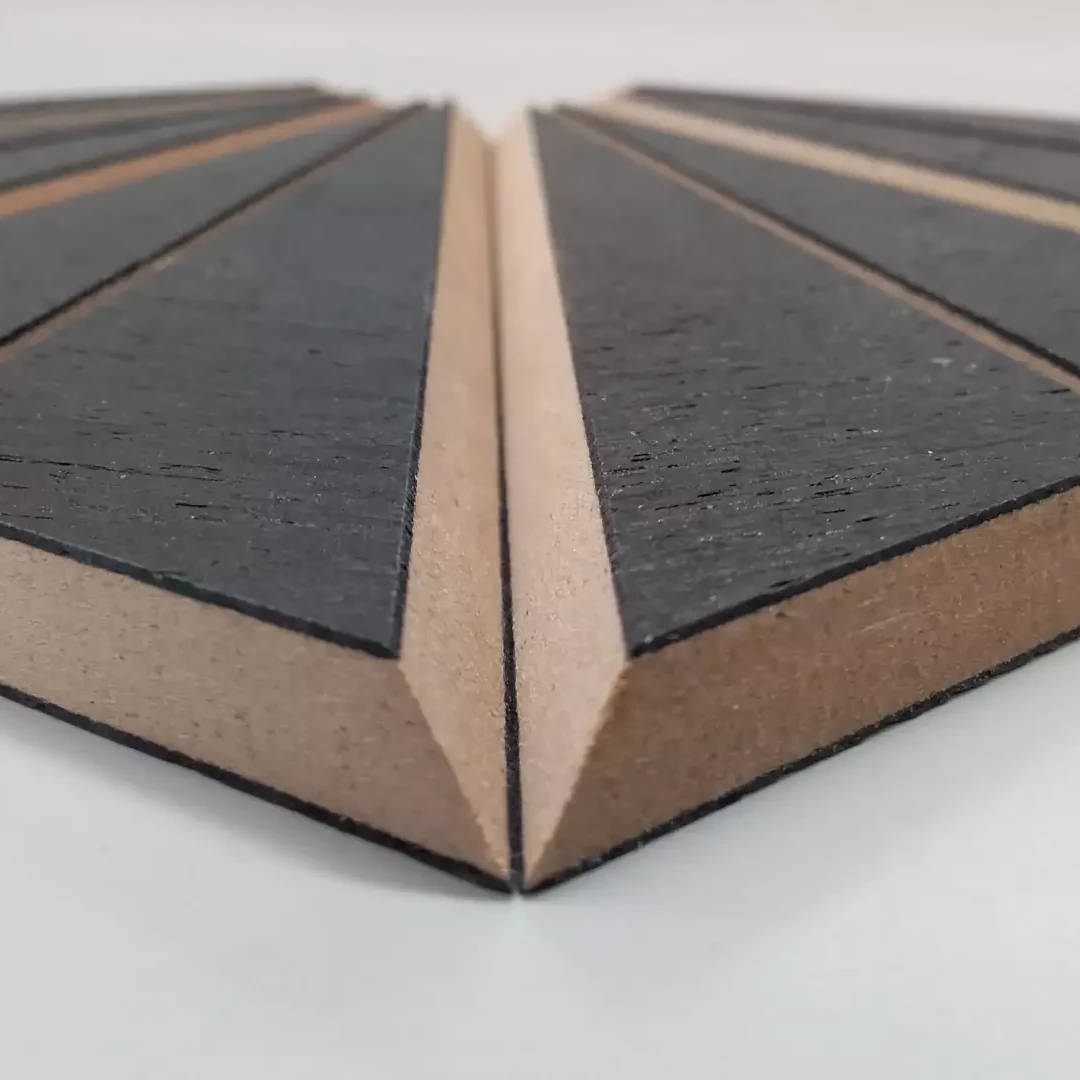

Cut 45°

The 45 cut allows you to join two pieces of wood ( or other materials) in a harmonious way, creating a perfect and flawless 90° angle.

By using woody essences, Fca is able to create 45° objects, hiding the seam edges, ensuring regular and mature continuation of the grain and uniformity of color.

This technique guarantees strength and aesthetics.

Woodworkings

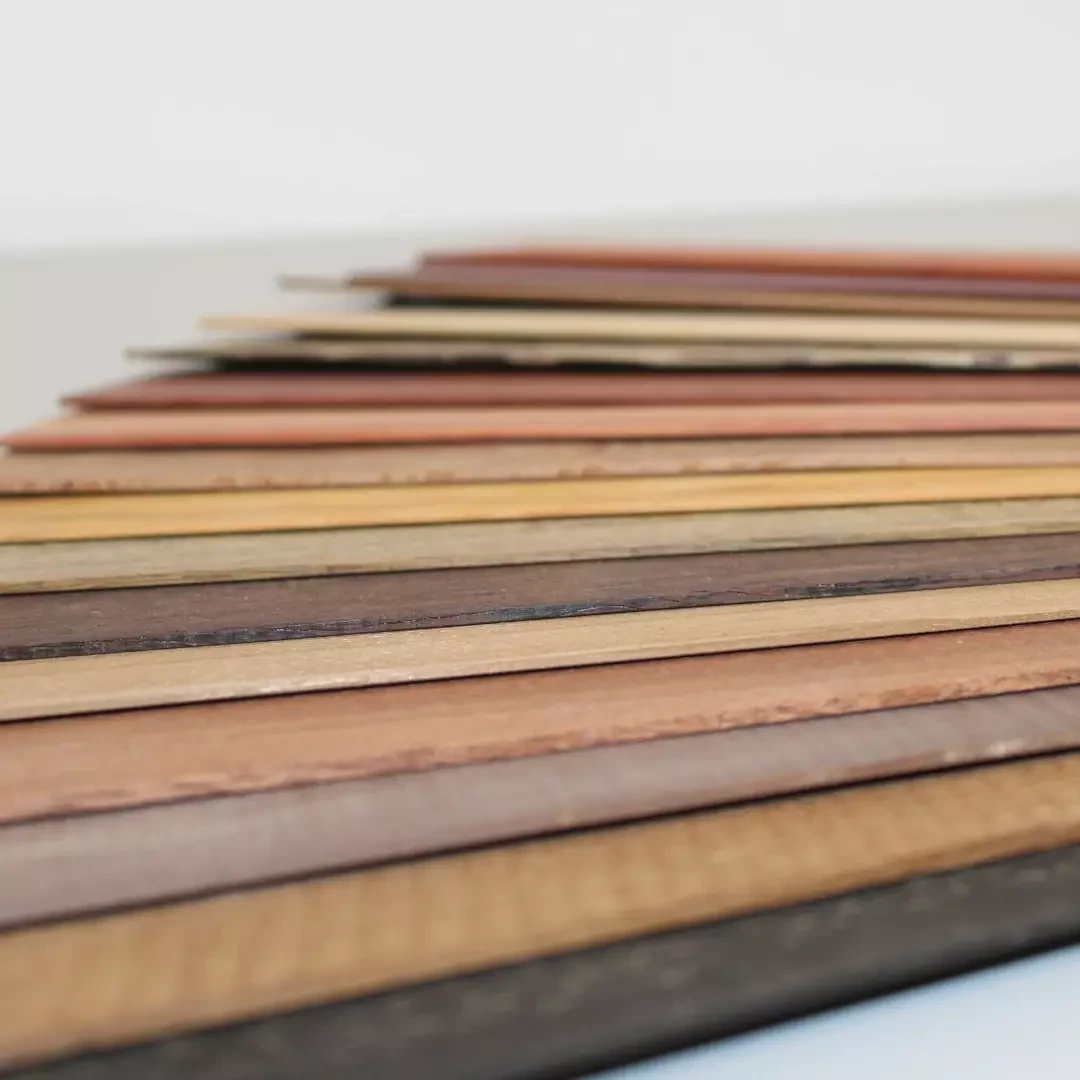

Thin cut

The thin cut is a technique that allows to obtain margins of thickness of 6 tenths of a millimeter. Fca performs this process using special machines that, combined with the skill of the staff is able to meet the needs of the customer.

Woodworkings

3D workings

Fca starting from a 3D CAD drawing of the customer, applies tools on suitable and specific CNC machines, designed for the faithful realization of the idea in an object. The final result will respect a high geometric precision.

Woodworkings

Engraving

FCA uses the engraving technique by generating engraving paths of the y,x and z axes of the CNC machines in the company. Applied on wood or other materials it becomes a real modern artistic form, traits of extreme precision and uniformity even of small details.

Woodworkings

Straightening and unframing

Fca employs for straightening and unframing, machines that guarantee an even greater increase in production and precision machining, in the order of a few hundredths of a millimeter. Thanks to the high speed, these machines are able to meet large and small quantities.

The latest addition to Fca, is a CNC machine that can perform profiles and shapes of two hundredths of a millimetre of tolerance. With measurement, which can also take place while the machinery is in action, we can ensure extreme precision for all production.

Woodworkings

Impregnation and stabilisation

Fca carries out impregnation and stabilisation processes, with the aim of preserving the structure of the wood, protecting it from external factors.

Reinforcing and lasting effect of the final product, both internally and externally. These treatments penetrate deep into the pores of wood making it “mechanical”.